Search This Supplers Products:TarpaulinPoly TarpsPVC TarpaulinShade NetLandscape FabricPE Tarpaulin

What is Fabric GSM and How to Measure It?

When we buy fabric, one term we often hear is GSM. It’s a very important attribute of a fabric because along with many other factors the price and comfort depend heavily on it. Also, different type of knitting stitches and woven structures give rise to different GSM values. In this article, we’ll provide you an in-depth look into what is fabric gsm and how do we measure fabric gsm. Without further ado, let’s jump right in.

For measuring the GSM, we need to measure the crimp percentage first. The measurement of warp crimp and weft crimp percentages formula are mentioned below:

Crimp Percentage of Warp Yarn

You need to use the following equation to get the crimp% of the warp –

Crimp% of Warp Yarn = {(Length of the Warp in Straight Condition – Length of the Warp in Fabric Formation) ÷ Length of the Warp in Fabric Formation} × 100

Crimp Percentage of Weft Yarn

You need to use the following equation to get the crimp% of the weft –

Crimp% of Weft Yarn = {(Length of the Weft in Straight Condition – Length of the Weft in Fabric Formation) ÷ Length of the Weft in Fabric Formation} × 100

We can use this formula to determine the GSM of given woven fabric:

Woven Fabric GSM = [{(Ends Per Inch × Warp Crimp Factore) ÷ Warp Count} + {(Picks Per Inch × Weft Crimp Factore) ÷ Weft Count}] × 23.5

Now by putting down all the value from a sample, we can easily determine GSM value for a woven fabric.

We can use either of these formula to determine the GSM for knit fabric:

Fabric GSM with Direct Count(Tex) = Course Per Inch × Wales Per Inch × Stitch Length in mm × Yarn Count in Tex × 0.001549

Fabric GSM with Indirect Count(Tex) = (Course Per Inch × Wales Per Inch × Stitch Length in mm × 0.9155) ÷ Yarn Count in Ne

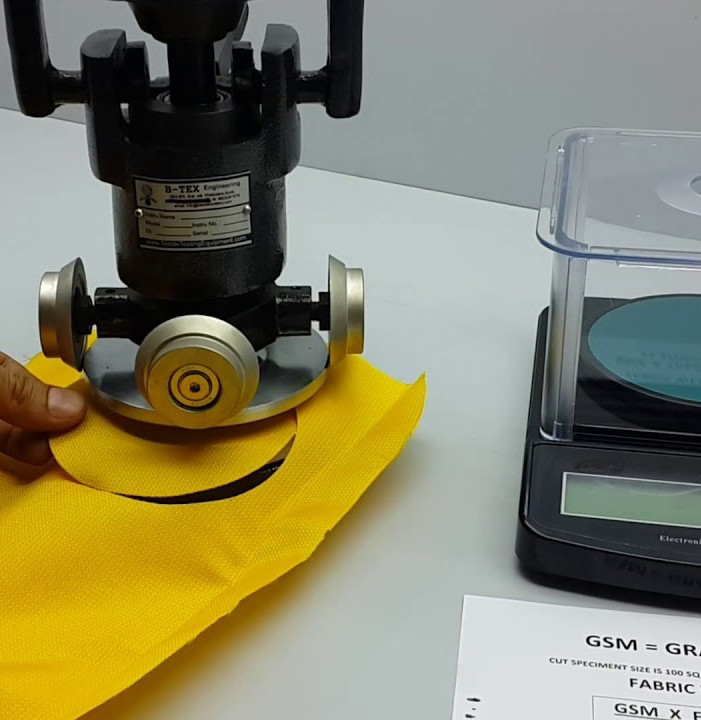

How Does GSM Cutter Machine Work

Step 1: Condition the Fabric

Firstly, take a sample from the main fabric and reserve it for conditioning. The conditioning time may vary from fabric to fabric because it depends on the nature of the fabric.

Step 2: Placing It over the GSM Pad

When the conditioning time is over, then the fabric is placed on the GSM pad to avoid crinkle and crease. Then the GSM cutter is placed on the fabric.

Step 3: Cut the Fabric

Now, with the hand-driven metal knob, we have to cut the fabric, maintaining a steady pressure.And thus, the fabric is finally cut into 11.2 cm in diameter.

Step 4: Weigh the Fabric

Then we have to move the machine and take the fabric for weighting on the electronic balance to have an accurate measurement.

Step 5: Calculate the GSM

The formula for measuring GSM by GSM cutter machine:

GSM=Specimen Weight(gram)x100

After weighing the value of the cut specimen, we have to multiply the value with 100 and then calculate it.

The calculated result is the GSM value for the fabric.

For more accuracy, we should cut the fabric sample from five different places of the main fabric and measure the weight. After calculating the mean value, we have to multiply it by 100 just like before.