Geotex-Needle Punch Non-Woven Fabric

- group name

- Geotextiles

- Min Order

- 5000 kilogram

- brand name

- TAIMEI Tarpaulin Shade Fabric Manufacturer

- model

- NWF-P001

- Nearest port for product export

- Qingdao Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Sat, 21 Feb 2026 15:24:46 GMT

Paramtents

Material Polypropylene or Polyester

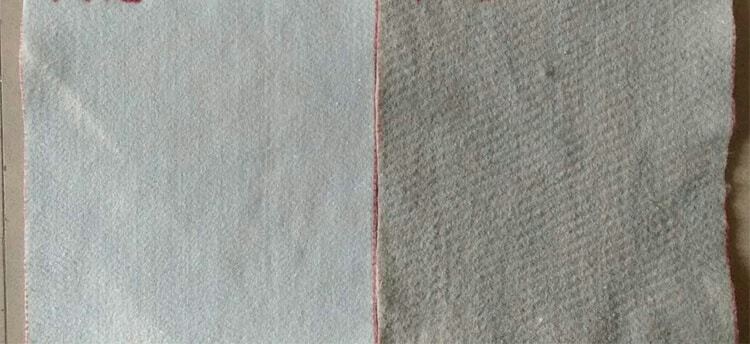

Color Black, White, Milky White

Application Geotextile

Weight 100 to 400gsm

Packging & Delivery

-

Min Order5000 kilogram

Briefing

Detailed

-

Introduction

|

|

|

|---|---|

|

Teratuf Non-woven Fabric (Geotex) is Continuous Filament Needle punched non-woven fabric made from Polyester/Polypropylene material, formed by the process of needle punching and thermally bounding, offers optimum performance per unit weight. It resist ultraviolet deterioration, rotting, biological degradation, naturally encountered basics, and acids which are used in many applications such as drainage, filtration, separation, and soil reinforcement. They function by restricting soil particles but allowing liquid and gases to easily pass through them and are used to improve the performance of environmental engineering, civil engineering, and construction projects including roads, railways, and landfills. We have both PP Long fiber and PET Short Fiber Non Woven Fabric. It can be used for differnt application according to it's physical and chemical charactors. |

|

Material Specification of PP Long Fiber: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Material Specification of PET Short Fiber:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|---|

Advantages:

- Excellent chemical compatibility.

- Long-term performance in strength and durability.

- Extends road and railway life.

- Cost-effective environmental alternative to traditional construction materials.

- Prevents banks from soil erosion.

- Easy to install.

Common Applications:

|

|

|---|

Colors Available:

- color

- color

Applications:

-

Landscape Fabric

Durable & Heavy Duty Gardening Mat. -

Garden Weed Barrier

Lets more water, air and nutrients into your plants while eliminating weed growth. -

Multch Film

Used to modify soil temperature, limit weed growth